JIAXING VIIPLUS INTERNATIO NAL TRADING CO.,LTD

Beyond Grease: A Deep Dive into Oilless Bushings & Why Viiplus

Leads the Way

Friction is the enemy of efficiency. In countless machines, from

massive industrial equipment to intricate automotive components,

the constant battle against wear and tear dictates performance,

longevity, and maintenance costs. Traditionally, grease and oil

have been the go-to solutions, but they come with their own set of

challenges: frequent re-lubrication, potential contamination,

environmental concerns, and limitations in extreme conditions.

Enter the world of oilless bushings, also known as self-lubricating bearings or sliding bearings. These innovative components offer a smarter way to manage

friction, delivering reliable movement without the need for

external lubrication.

At Viiplus (www.viiplus.com), we don't just supply these components; we engineer solutions.

Leveraging deep expertise in metallurgy and tribology (the science

of friction, wear, and lubrication), we've become a leading name in

sliding bearing technology. But what exactly are oilless bushings, and why should they be on your radar? Let's dive

deeper.

What Exactly Are Oilless Bushings? The Science of Self-Lubrication

Unlike traditional ball or roller bearings that rely on rolling

elements and require constant lubrication films, oilless bushings

operate on the principle of sliding motion. Their "magic" lies in their material composition and structure,

designed to provide their own lubrication at the bearing surface.

This can be achieved through several key technologies:

Solid Lubricants Embedded: Materials like graphite, MoS₂, or PTFE are embedded directly into

the metallic matrix (often bronze) of the bushing. As the shaft

rotates or slides, a minuscule amount of this solid lubricant is

transferred to the mating surface, creating a low-friction film.

Porous Metal Structures: Sintered bronze or iron materials are created with microscopic

pores. These pores are vacuum-impregnated with oil during

manufacturing. In operation, slight heating causes the oil to

expand and seep onto the bearing surface, providing lubrication.

When it cools, the capillary action draws the oil back in, creating

a closed-loop system.

Layered Composites: These often feature a strong backing (like steel), an intermediate

sintered layer (like bronze), and a low-friction overlay (often

PTFE-based). The PTFE layer provides the primary sliding surface,

offering extremely low friction.

Contrasting Logic: Oilless vs. Traditionally Lubricated Bearings

| Lubrication | Internal / Self-Contained | Requires External Grease/Oil Application |

| Maintenance | Minimal to None (Maintenance-Free) | Regular Re-lubrication Schedule Required |

| Contamination | Low Risk (No external grease traps dirt) | High Risk (Grease attracts and holds contaminants) |

| Operating Temp. | Wider Range (Specific material dependent) | Often Limited by Grease/Oil Properties |

| Cleanliness | High (No leakage) | Potential for Grease/Oil Leakage |

| Design | Simpler (No grease nipples/pathways) | More Complex (Requires lubrication access) |

| Initial Cost | Potentially Higher | Potentially Lower |

| Total Cost (TCO) | Often Lower (Reduced maintenance, downtime) | Can be Higher (Lubricant, labor, downtime costs) |

The Tangible Benefits: Why Make the Switch?

Choosing oilless bushings isn't just about eliminating grease guns.

It's about unlocking significant operational advantages:

Drastically Reduced Maintenance: This is the most obvious benefit. No re-greasing means less labor,

less scheduled downtime, and simplified maintenance protocols.

Imagine the savings across a factory floor!

Enhanced Reliability: Lubricant starvation is a major cause of bearing failure.

Self-lubricating bearings ensure consistent lubrication, leading to

predictable performance and longer service life, especially in

hard-to-reach locations.

Superior Performance in Harsh Conditions: Oilless bushings excel where traditional lubricants fail:

High Temperatures: Certain types can operate at temperatures far exceeding the limits

of conventional greases.

Low Temperatures: No grease means no stiffening or freezing issues.

Contaminated Environments: The absence of sticky grease reduces the ingress of dirt, dust, and

debris.

Vacuum or Underwater: Ideal for applications where liquid lubricants are impractical or

impossible.

-

-

-

Cost Savings (Total Cost of Ownership): While the initial purchase price might sometimes be higher, the TCO

is often significantly lower due to savings on lubricants, labor,

downtime, and potential component failure replacement.

Environmental Friendliness: Eliminating oil and grease leakage prevents contamination of

products, machinery, and the environment. Crucial for industries

like food processing, pharmaceuticals, and textiles.

Compact & Simplified Designs: Without the need for lubrication systems (nipples, lines,

reservoirs), machine designs can be more compact and streamlined.

Exploring Viiplus's Portfolio: Finding Your Solution

Viiplus offers a comprehensive range of self-lubricating bearings

designed to meet diverse application needs. Understanding the

different series helps in selection:

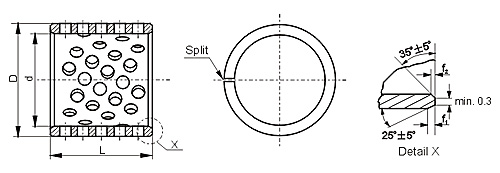

JDB Series (Graphite Plugged Bronze): Excellent for high-load, low-speed applications, intermittent

motion, and high temperatures. The graphite plugs provide

continuous solid lubrication. Ideal for heavy machinery, molds, and

hydraulic components.

SF Series (PTFE-Based Composite): Typically metal-backed (SF-1: steel, SF-2: steel/bronze) with a

PTFE-based lining. Offers very low friction, good wear resistance,

and suitability for dry running or marginal lubrication. Common in

automotive, office equipment, and hydraulics.

JF Series (Bimetal Bushings): Combines a steel backing with a sintered bronze or lead-bronze

lining. Good load capacity and fatigue strength. Often used with

grease or oil but can operate marginally lubricated. Found in

engines, chassis parts, and agricultural machinery.

FB Series (Wrapped Bronze): Often made from bronze strip, sometimes with lubrication pockets or

through-holes. A cost-effective solution for medium loads and

speeds, typically requiring initial greasing but offering extended

re-lubrication intervals.

Quick Comparison Chart (General Guide):

| JDB (Graphite Plugged) | Very High | Low | Very High | Excellent | Heavy Industry, Molds, High Temp Equipment |

| SF-1 (PTFE Composite) | High | Moderate | Moderate | Excellent | Automotive, Hydraulics, General Machinery |

| JF (Bimetal) | High | Moderate | Moderate | Limited | Engines, Transmissions, Construction Equip. |

| FB (Wrapped Bronze) | Moderate | Moderate | Moderate | Poor (Needs Lube) | General Purpose, Linkages, Pivot Points |

(Note: This is a simplified guide. Always consult specific product

data sheets or Viiplus experts for precise application

requirements.)

Uncertain which material or type suits your project? Our Bushing Material Selection Guide is designed to help, or Contact Us for a Free Quote and Expert Advice.

Why Partner with Viiplus? Expertise Meets Quality

Choosing the right supplier is as critical as choosing the right

bushing. Here’s why companies worldwide trust Viiplus:

Deep Expertise: Our foundation in metallurgy and tribology, coupled with a talented

R&D team, means we understand the science behind reliable

movement. We don't just sell; we solve friction challenges.

Uncompromising Quality: We employ advanced manufacturing techniques (including sand

casting, centrifugal casting, metal casting, investment casting)

and a rigorous quality management system, ensuring every bushing

meets the highest standards.

Comprehensive Range: From standard metric sizes in JDB, SF, JF, and FB series to custom

solutions including cylindrical, flange, double flange bushings,

wear plates, and guide rails – we have the portfolio to match your

needs.

Global Reach, Seamless Logistics: Based in China, we ship sliding bearings worldwide. Our

professional team handles customs clearance efficiently, ensuring

smooth, timely delivery with all necessary documentation.

Customer-Centric Approach: We believe in ethical practices and building trust. We offer

flexible production (single units to large series), competitive

pricing, and online support.