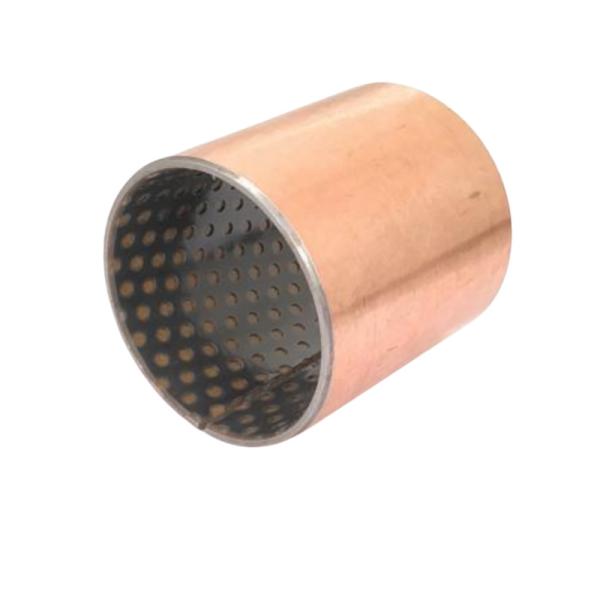

Marginal Lubrication Bearing Steel Backing DIN 1494 Standard refers

to a type of bearing component that incorporates a steel backing

with marginal lubrication features, adhering to the DIN 1494

standard. This standard specifies the requirements for the design,

material, and performance of such bearings, ensuring their

reliability and durability in various industrial applications.

The steel backing provides a rigid and stable foundation for the

bearing, supporting the load and maintaining the shape and position

of the bearing surface. The marginal lubrication feature allows for

effective lubrication even in conditions where traditional

lubrication methods may be inadequate. This helps to reduce

friction and wear, extending the bearing's lifespan and improving

its performance.

By adhering to the DIN 1494 standard, Marginal Lubrication Bearing

Steel Backing ensures compliance with industry-recognized quality

and safety requirements. This ensures that the bearings are

suitable for use in a wide range of industrial settings, including

high-load and high-speed applications.

In summary, Marginal Lubrication Bearing Steel Backing DIN 1494

Standard offers a robust and reliable bearing solution that

combines the strength and stability of steel with effective

marginal lubrication. This combination ensures smooth and efficient

operation, reduced wear, and longer bearing lifespan, making it a

valuable addition to any industrial equipment or machinery.

Marginal Lubrication Bearing Steel Backing DIN 1494 Standard

Customized Self-Lubricating Bushing In High Temperature Condition

Overview

Oil-free self-lubricating bearing oil pit polyformaldehyde

wear-resistant composite shaft sleeve copper sleeve with oil

injection hole

Quick Details

Applicable Industries:Manufacturing Plant

Size | customizable |

Certification | ISO9001 |

Processing methods | Cold-extrusion |

Surface treatment | Tin plating /Copper plating |

Operating temperature | -150~250 |

Application field | High pressure gear pump, High pressure water injection pump, High

pressure hydraulic motor, Painting and food processing, etc. |

Material | Steel base+ Bronze powder+(POM) |

Marginal Lubrication Bearing Steel Backing DIN 1494 Standard

Features:

Lubrication Bearing Steel Backing Suitable for dry running, low coefficient of friction, lower wear,

good sliding characteristics, the transfer film created can protect

the mating metal surfaces, suitable for rotating and oscillating

movement, high chemical resistance, low absorption of water and

swelling. The bushing improved the friction and much good wear

resistance over the common range under lubricated operation.

Tech. Data:

| Max. load | Static | 250N/mm2 | Max.speed | Dry running | 0.08~0.20 |

| Very low speed | 140N/mm2 | Hydrodynamicoperation | 0.02~0.08 |

| Rotatingoscillating | 60N/mm2 | Friction coefficient | Dry | 2m/s |

| Hydrodynamic | >2m/s |

| Max. PVdryrunning) | Short-term operation | 3.6N/mm2*m/3 | Thermal conductivity | 42W(m*K)-1 |

| Continuous operation | 1.8N/mm2*m/3 |

| PV max. hydrodynamic | -195℃~+280℃ | Coefficient of thermalexpansion | 11*10-6*K-1 |

Structure:

1. /Fibre mixture thickness 0.01~0.03mm. It is the contact surface

for the rotating shaft. Minute parties of the layer and the

sintered bronze material combine to create a solid lubricant film,

which coats the shaft.

2. Sintered bronze powder thickness 0.20*0.35mm, A special

composition of powdered copper is thermally fused to the steel

backing. This contact layer acts as an anchor for the layer and

conducts the thermal build-up away from the bearing surfaces.

3. Low-carbon steel backing. Setting the foundation of the

bushings, the steel back provides exceptional stability, load

carrying, and heat dissipation characteristics.

Typical Applications:

1. This material meets the demanding criteria for long life and

maintenance-free performance with or without lubrication.

Automotive: tractors, combines, crop sprayers, earth-movers,

graders and other construction, auto machines, specific uses in

power steering cylinders, steering gear thrust washers, disc

brakes, calipers and pistons, shock absorbers, governor linkage,

windshield wiper motor, tilt gear assemblies...

2. Business machines: photocopy machines, typewriters, mail

sorters, postage meter systems, computer terminal printers and

peripheral equipment,automatic printing devices, mail processing

machinery...

Hydraulics and valves: pumps including gear, rotary, water, axial

piston, and other types, ball, butterfly, poppet steam, and other

valves and valve trunnions...

3. Home appliances: tape recorders, refrigerators, air

conditioners, cleaners, polishers, sewing machines, ovens,

dishwashers, clothes washing machines...And materials handling,

marine engine, packaging, textile equipment, tools...etc.

| d | d | axle | housing h7 | wall thickness | h oil hole | f 1 | f 2 | l 0 -0.40 |

|---|

| min | max | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

|---|

| 10 | 12 | 10 -0.022 | 12 +0.018 | 0.955 | 0.980 | 4 | 0.6 | 0.3 | 1010 | 1015 | 1020 | | | | | | | |

|---|

| 12 | 14 | 12 -0.027 | 14 +0.018 | 1210 | 1215 | 1220 | | | | | | | |

|---|

| 14 | 16 | 14 -0.027 | 16 +0.018 | | 1415 | 1420 | | | | | | | |

|---|

| 15 | 17 | 15 -0.027 | 17 +0.018 | | 1515 | 1520 | 1525 | | | | | | |

|---|

| 16 | 18 | 16 -0.027 | 18 +0.018 | | 1615 | 1620 | 1625 | | | | | | |

|---|

| 18 | 20 | 18 -0.027 | 20 +0.021 | | 1815 | 1820 | 1825 | | | | | | |

|---|

| 20 | 23 | 20 -0.033 | 23 +0.021 | 1.445 | 1.475 | 0.6 | 0.4 | | 2015 | 2020 | 2025 | 2030 | | | | | |

|---|

| 22 | 25 | 22 -0.033 | 25 +0.021 | | 2215 | | 2225 | | | | | | |

|---|

| 25 | 28 | 25 -0.033 | 28 +0.021 | 6 | | 2515 | 2520 | 2525 | 2530 | | | | | |

|---|

| 28 | 32 | 28 -0.033 | 32 +0.025 | 1.935 | 1.970 | 1.2 | 0.4 | | | 2820 | | 2830 | | | | | |

|---|

| 30 | 34 | 30 -0.033 | 34 +0.025 | | | 3020 | 3025 | 3030 | 3035 | 3040 | | | |

|---|

| 35 | 39 | 35 -0.039 | 39 +0.025 | | | 3520 | | 3530 | 3535 | 3540 | | | |

|---|

| 40 | 44 | 40 -0.039 | 44 +0.025 | 8 | | | 4020 | | 4030 | 4035 | 4040 | | 4050 | |

|---|

| 45 | 50 | 45 -0.039 | 50 +0.025 | 2.415 | 2.460 | 1.8 | 0.6 | | | 4520 | | 4530 | | 4540 | 4545 | 4550 | |

|---|

| 50 | 55 | 50 -0.039 | 55 +0.030 | | | | | 5030 | | 5040 | | 5050 | 5060 |

|---|

| 55 | 60 | 55 -0.046 | 60 +0.030 | | | | | 5530 | | 5540 | | 5550 | 5560 |

|---|

| 60 | 65 | 60 -0.046 | 65 +0.030 | | | | | 6030 | | 6040 | | 6050 | 6060 |

|---|

| d | d | axle | housing h7 | wall thickness | hoil hole | f 1 | f 2 | l 0 -0.40 |

|---|

| min | max | 40 | 50 | 60 | 80 | 90 | 95 | 100 | 110 | 120 |

|---|

| 65 | 70 | 65 -0.046 | 70 +0.030 | 2.415 | 2.460 | 8 | 1.8 | 0.6 | 6540 | | 6560 | | | | | | |

|---|

| 70 | 75 | 70 -0.046 | 75 +0.030 | 7040 | 7050 | | 7080 | | | | | |

|---|

| 75 | 80 | 75 -0.046 | 80 +0.030 | 7540 | | 7560 | 7580 | | | | | |

|---|

| 80 | 85 | 80 -0.046 | 85 +0.035 | 2.385 | 2.450 | 9.5 | 1.8 | 1.8 | 8040 | | 8060 | 8080 | | | | | |

|---|

| 85 | 90 | 85 -0.054 | 90 +0.035 | 8540 | | 8560 | 8580 | | | | | |

|---|

| 90 | 95 | 90 -0.054 | 95 +0.035 | 9040 | | 9060 | 9080 | 9090 | | | | |

|---|

| 100 | 105 | 100 -0.054 | 105 +0.035 | | 10050 | | 10080 | | 10095 | | | |

|---|

| 105 | 110 | 105 -0.054 | 110 +0.035 | | | 10560 | 10580 | | 10595 | | 105110 | |

|---|

| 110 | 115 | 110 -0.054 | 115 +0.035 | | | 11060 | 11080 | | 11095 | | 110110 | |

|---|

| 120 | 125 | 120 -0.054 | 125 +0.040 | 1.8 | 0.6 | | | 12060 | 12080 | | | | 120110 | |

|---|

| 125 | 130 | 125 -0.063 | 130 +0.040 | | | 12560 | | | | | 125110 | |

|---|

| 130 | 135 | 130 -0.063 | 135 +0.040 | | 13050 | 13060 | 13080 | | | 130100 | | |

|---|

| 140 | 145 | 140 -0.063 | 145 +0.040 | | 14050 | 14060 | 14080 | | | 140100 | | |

|---|

| 150 | 155 | 150 -0.063 | 155 +0.040 | | 15050 | 15060 | 15080 | | | 150100 | | |

|---|

| 160 | 165 | 160 -0.063 | 165 +0.040 | 9.5 | | 16050 | 16060 | 16080 | | | 160100 | | |

|---|

| 170 | 175 | 170 -0.063 | 175 +0.040 | | 17050 | | 17080 | | | 170100 | | |

|---|

| 180 | 185 | 180 -0.063 | 185 +0.046 | | 18050 | 18060 | 18080 | | | 180100 | | |

|---|

| 190 | 195 | 190 -0.072 | 195 +0.046 | | 19050 | 19060 | 19080 | | | 190100 | | 190120 |

|---|

| 200 | 205 | 200 -0.072 | 205 +0.046 | | 20050 | 20060 | 20080 | | | 200100 | | 200120 |

|---|

| 220 | 225 | 220 -0.072 | 225 +0.046 | 9.5 | | 22050 | 22060 | 22080 | | | 220100 | | 220120 |

|---|

| 240 | 245 | 240 -0.072 | 245 +0.046 | | 24050 | 24060 | 24080 | | | 240100 | | 240120 |

|---|

| 250 | 255 | 250 -0.072 | 255 +0.052 | | 25050 | 25060 | 25080 | | | 250100 | | 250120 |

|---|

| 260 | 265 | 260 -0.081 | 265 +0.052 | | 26050 | 26060 | 26080 | | | 260100 | | 260120 |

|---|

| 280 | 285 | 280 -0.081 | 285 +0.052 | | 28050 | 28060 | 28080 | | | 280100 | | 280120 |

|---|

| 300 | 305 | 300 -0.081 | 305 +0.052 | | 30050 | 30060 | 30080 | | | 300100 | | 300120 |

|---|