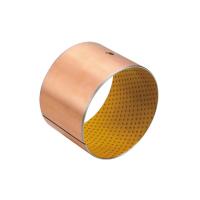

CC495K/CuSn10Pb10 bimetal bronze bushings and strip sheet materials

refer to a type of composite material composed of a steel backing

layer and a bronze overlay layer. The steel backing layer provides

strength and dimensional stability, while the bronze overlay layer,

which typically consists of CuSn10Pb10 (also known as 10-10-10

bronze), offers excellent wear resistance, corrosion resistance,

and self-lubricating properties.

ASTM standards define the physical, chemical, and mechanical

properties of materials to ensure consistency and quality. For

CC495K/CuSn10Pb10 bimetal bronze bushings and strip sheet

materials, ASTM standards would specify the composition of the

bronze overlay, the thickness of the overlay, the strength and

hardness of the steel backing, and other relevant properties.

CuSn10Pb10 bronze is a popular alloy for bimetal bushings and strip

sheet materials due to its good machinability, wear resistance, and

corrosion resistance. It is commonly used in applications where

sliding contact and self-lubricating properties are critical, such

as bearings, bushings, gears, and slides.

CC495K/CuSn10Pb10 bimetal bronze bushings and strip sheet materials

are widely used in various industries, including automotive,

construction, heavy machinery, and more. They offer a

cost-effective solution for applications requiring high wear

resistance and long service life. By meeting ASTM standards, these

materials ensure consistent performance and reliability.

CC495K / CuSn10Pb10 Steel Bimetal Bronze Bushing

Steel Type G-CuPb10Sn Bimetal Bushing & Plain Bearings Manufacturer.Leaded Bronze Castings Bimetal Plain

Bearings to Standard C93700 SAE 792 SAE 798 JF 800 Rg7.Are your

bimetal bronze steel bushings Steel + CuPb10Sn10 with indents worn? Updating your plain bearings a need quality

replacement parts? We carry a complete line of bushings strips &

materials for just about any self-lubricating bearings.Bimetal

Plain Bearings Strips & Plate,Bearing forms made to order:

Cylindrical bushes and sliding plates with non-standard dimensions,

RoHS customized bearing designs.

DIN-G-CuPb10Sn

Pb(%) | Fe(%) | Ni(%) | Zn(%) | Cu(%) |

|---|

8.0-11.0 | ≦0.25 | ≦1.5 | ≦2.0 | 78.0-87.0 |

Jf-800 bimetallic bearing

JF bimetal composite bearings with high quality low carbon steel as substrate, the surface of the sinter with low friction properties of copper alloy (CuPb10Sn10 CuPb6Sn6Zn3 CuPb24Sn4,

CuPb30, AlSn20Cu, CuSn8Ni) as wear-resisting layer of bearing, can need according to the operating conditions

of copper alloy surface processing of various types of oil tank,

oil hole, hole, etc., in order to suit to cannot continue to go

hard or go occasion.Good bonding strength and optimum bearing

capacity can be obtained by secondary sintering and secondary

extrusion.

Availability

Bearing forms available in standard dimensions

Cylindrical bushes

Thrust washers

Strips

Material

Steel Backing and Leaded Bronze Overlay

Steel + CuPb10Sn10 with indents

Sliding layer with lubrication indents

CuPb10Sn10 with

composition approx.:

Cu 80 %

Pb 10 %

Sn 10 %

Steel backing

Steel+CC495K /CUSN10PB10

CuPb10Sn10 is normally replaced by alloy Rg7, which is an alloy with similar characteristic and performance despite lower lead-content.

Product Description

Chemical composition (nom.)

– Cu 78-82 %

– Pb 8-11 %

– Sn 9-11 %

Max. impurities

– Ni 2,0 % (can be part of the Cu-content)

– P 0,05 %

– Zn 2,0 %

– S 0,10 %

– Fe 0,25 %

– Mn 0,2 %

– Al 0,01 %

– Si 0,01 %

– Sb 0,5 %

High load capacity

Sliding layer can be machined with lubricating grooves and/or with

grease indents

Steel backing can be copper plated.

The company strictly complies with ISO 9001:2000 international

quality management system certification, and adopts German DIN1494

as the enterprise standard to establish a sound strips structure

and constantly improve the production process.

Technical Parameters

Alloy layer material: CuPb10Sn10

Maximum applicable temperature: 260℃

Friction coefficient: ≤0.12

Alloy layer hardness :(60~90)HB

Characteristics

- Lead-free

- Machinable

- Design freedom – customizable to meet specific indentation and

shape needs

- Capable of supporting high specific loads and high temperatures

- Excellent fatigue strength under dynamic and shock load conditions

- Excellent wear resistance

- Suitable for hydrodynamic operation

- Suitable for oil and grease lubrication

- Superior performance under oscillating movement

- Thin-wall construction permits compact bearing assembly

- Indents in the bearing surface provide a reservoir for grease and

thus allow extended re-greasing

Application:

Industrial – Agricultural machinery, earth-movers, textile

machinery, pneumatic equipment, mechanical handling and lifting

equipment, hydraulic cylinders, offhighway equipment, and many

more.