ROHS compliant straight steel (Polytetrafluoroethylene) sleeve

bushings with flanged bearings and lead-free washers are designed

for applications requiring high chemical resistance, low friction,

and environmental compliance. These bushings feature a steel outer

shell for durability and a lining for smooth operation. The

lead-free washers ensure compliance with environmental regulations

and provide a secure fit.

The LBM (Loose-to-Bore Match) tolerance specification refers to the

clearance or interference between the bushing's inner diameter and

the mating shaft or bore. This tolerance ensures proper

installation and function while minimizing wear and friction. The

specific LBM tolerance values depend on the size and series of the

bushing, and should be referenced in the manufacturer's

specifications or catalog.

The flanged design of these bushings allows for easy installation

and secure positioning within the application. The lining provides

excellent chemical resistance and low friction properties, ensuring

smooth and consistent operation.

Please note that the exact tolerance values and technical

specifications may vary depending on the manufacturer and specific

application requirements. It is important to consult the

manufacturer's catalog or specifications for detailed information

on the LBM tolerance and other relevant parameters.

composite sliding bushing is one of the most common bushing

materials used worldwide due to its numerous advantages. Due to its

thin wall thickness even at bigger diameters, it can be easily used

for applications that do not allow a lot of bearing space, yet it

delivers a very high load capacity as well as one of the lowest

friction values among all bushing materials – and still being

maintenance-free!

Composite dry sliding bearings– maintenance-free and

space-saving,Plain bushings composite metric size PCM B Bore diameter 3 mm – 300 mm Self lubricating bearings –200 to +250 °C,inch size bushing also available: PCZ .. B 0,125 – 7 inch size oilless bushing made to order from china.

Cylindrical bushing, sliding stripes,

...more than 50 pcs. available

Price after login

1. Inner dimension

2. Outer dimension

3. Length

The composite bushing belongs to the family of coated or split

bushes. It is produced according to a DIN standard, which means

that ID and OD and their tolerances are set in an international

standard. The bushings are manufactured from a plate material,

which consists of a support material, in this case steel. It is

coated with in a sintering furnace using bronze powder as the

bonding agent between and steel. Sintered bronze plays a very

important role for this material, as without it, would easily

detach from the support material.

Material:

Steel Back + Porous Bronze Sinter + + Lead

■Lubrication-free

■Corrosion resistance

■Resistant to dust and dirt

■Small friction coefficient

composite sliding stripes Technical Data

| Sliding surface: | |

| Support material: | Tin plated steel |

| Dynamic load: | ≤ 140 N/mm² |

| Static load: | ≤ 250 N/mm² |

| Sliding speed: | ≤ 2,5 m/s |

| Fricition value: | 0,03 - 0,25 µ |

| max. PV-value: | 1,8 N/mm² x m/s |

| Temperature strain: | -200 up to +280 °C |

| Maintenance: | maintenance-free |

| Shaft material: | Steel, hardened or untempered, roughness Rz < 2-3 |

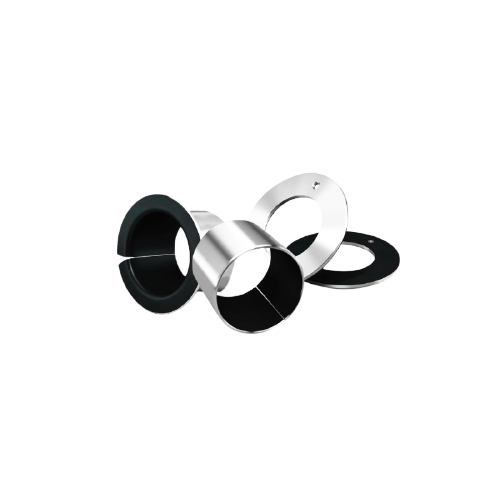

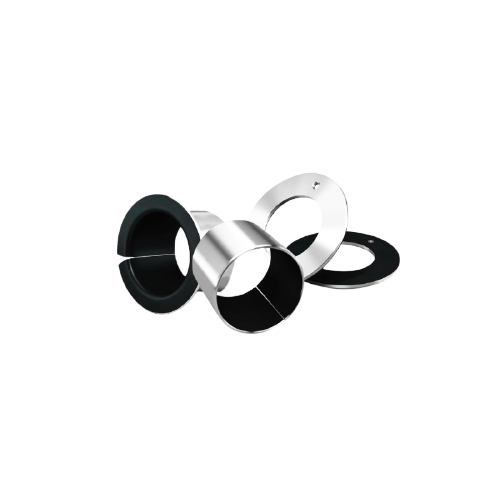

composite Thrust Washer

| Sliding surface: | |

| Support material: | Tin plated steel |

| Dynamic load: | ≤ 140 N/mm² |

| Static load: | ≤ 250 N/mm² |

| Sliding speed: | ≤ 2,5 m/s |

| Fricition value: | 0,03 - 0,25 µ |

| max. PV-value: | 1,8 N/mm² x m/s |

| Temperature strain: | -200 up to +280 °C |

| Maintenance: | maintenance-free |

| Tolerance housing: | H7 |

| Tolerance after mounting: | H9 |

| Shaft tolerance: | f7 or f8 |

| Shaft material: | Steel, hardened or untempered, roughness Rz < 2-3 |

Sliding Bearings Characteristics

The important characteristics of dry sliding bearings

composite bushes include

• freedom from maintenance

• no lubrication required

( composite)

• initial lubrication required

(POM composite)

• minimum wall thickness, minimum

space requirements

• can support heavy loads

• wide operating temperature range

• good sliding properties

• practically without stick-slip

• little wear

• insensitive to edge loads

(POM composite)

• no machining required

Which bronze bushing manufacturer is professional? How to choose a

reliable manufacturer?

Among the many different types of bronze bushing manufacturers, if

you want to choose a professional, reliable and trustworthy

manufacturer, you must understand the production and processing

strength and production and processing technology guarantees of

different manufacturers, especially through comparison and judgment

through various factors. Choose a few more manufacturers for

rational comparison, so as to narrow the selection range and avoid

blindly selecting manufacturers and affecting the quality and

function of production and processing.

1. Compare the manufacturer's service situation

To select a bronze bushing manufacturer, in addition to considering

the manufacturer’s production and processing technology level, it

is also necessary to determine the manufacturer’s specific service

situation and understand the manufacturer’s production mode and

service standards to determine wh the manufacturer is worthy of

cooperation.

2. Determine the quality of processing and production

If you want to choose a professional, reliable and trustworthy

bronze bushing manufacturer, it is recommended that you not only

need to understand the manufacturer’s production and processing

scale, but also determine wh the manufacturer’s production and

processing technology is mature and wh it has a complete production

and processing line. In terms of after-sales service guarantee Wh

they are comprehensive, these various issues must be rationally

considered and compared.

3. Understand the manufacturer's production scale

If you want to know which manufacturer is trustworthy, you can

understand the professional production level by comparing the

situation of different manufacturers. It has a good production

advantage in the production and processing process. By determining

the manufacturer's production scale and service guarantee, you can

understand the specific situation of the copper sleeve

manufacturer.

Bushings - Plain Bearings - Sleeve Bearings Type:

Bushings

Flanged bushings

Thrust washers

Self-lubricating Bearing strip

Composite Self-Lubricating Bushings / Plain Bearings Housing &

Shaft Bushes Tolerance

VIIPLUS CHINA BEARINGS produces only Self-lubricating Bearings for

a variety of applications, giving our customers solutions

advantages over other bearings.

QUALITY / ISO 9001 Oilless Resin Sliding Materials Manufacture

Standard Components for Sliding Bearings Material

Tolerances Bushing Products Size

OUR BUSHINGS ARE UTILIZED ON A GLOBAL SCALE

- General Applications

- Industrial Machinery

- Transportation Equipment

- Markets

- Water Handling Equipment

- Special Markets

- Aerospace

- Oil and Gas

- Power Transmission and Control

- Hydraulics

Nearly every market uses a viiplus bushing & sliding bearings in

some form. The following are a few specific markets that rely on

our bushes products:

Bushings are selected based on the velocity and the applied load.

Maintenance-free bushings do not require additional lubrication to

operate.

Bushing Bearings offers a variety of metal bushings including brass

bushings, steel bushing, & bronze bushings.

If you already know which type of metal bushing is right for your

application, you can quickly navigate to it below for more

information:

DU coated bushing - Oiles Bush,Oilless Bearing,Bronze Sleeve

Bearings | Products & Suppliers | China composite plain bearings

Description:OILLESS BEARINGS INDUSTRY Glide bearing is a

self-lubricating bearing material that consists of a high-quality

bearing bronze with pockets filled with solid lubricant and a thin

film of solid lubricant over the bearing surface to aid the

running-in process. Viiplus self lubricating bearings maintenance

Self-lubricating bushings strip plate sheet offer very good wear

and low friction performance over a wide range of loads, speeds and

temperatures in dry running conditions ...

Get access to VIIPLUS bearing drawings Ask for a quote Start your

project With an Application Engineer.

Technical Data - Metric Steel Back + Porous Bronze Sinter + + Lead

The ideal plain bearing for your requirements:

Special productions made from VIIPLUS strips are manufactured using

precision cutting and sheet metal working. A wide range of

different shapes and dimensions can be manufactured from

VIIPLUSmaterials, for example:

thrust washers in special dimensions

thrust washers with complex geometries

thrust washers with any inside diameter and any outside diameter up

to 230 mm

thrust washers in other designs such as counterbores, notches or

lugs

half-washers and washer segments

strip cuts

other strip designs, e.g. with notches or groove

slide path coverings

Special productions made from VIIPLUS strips are used in hydraulic

applications and compressors, for example.

Other special parts made from VIIPLUS strips

bent parts, e.g. angles, half-shells, U-profiles, rails

bearing shells

spherical sliding elements

half-shells with side elements (welding ensures firm

substance-to-substance bond)

drawing parts, customer-specific components

Advantages of special productions made from VIIPLUS sliding strips

small lot sizes can be manufactured

high material output

no tool costs

high degree of flexibility, e.g. products can be manufactured

quickly

no elastic deformation

intricate contours can be created

neat cut edges which often do not need to be remachined