CuZn25Al6Fe3Mn4, also known as C86300, is a type of graphite bronze

alloy that is commonly used as a material for bushing slider

washers and other sliding components. This alloy offers a unique

combination of properties that make it suitable for a wide range of

applications.

The addition of graphite particles in CuZn25Al6Fe3Mn4 bronze

provides excellent self-lubricating properties. Graphite is a

natural lubricant that reduces friction and wear between sliding

surfaces. This allows the bushing slider washers made from this

alloy to operate smoothly and efficiently, even under high loads

and speeds.

In addition to its self-lubricating properties, CuZn25Al6Fe3Mn4

bronze also possesses high strength and good corrosion resistance.

The alloy's copper-zinc base provides good ductility and toughness,

while the addition of aluminum, iron, and manganese improves its

mechanical properties and corrosion resistance. This makes the

alloy suitable for use in harsh environments and demanding

applications.

CuZn25Al6Fe3Mn4 bronze bushing slider washers are often used in

mechanical systems that require smooth and reliable sliding motion.

They are commonly found in automotive transmissions, industrial

machinery, and other applications where precise alignment and

smooth operation are critical.

The alloy's machinability is also a key advantage, as it can be

easily cut and shaped to meet specific application requirements.

This allows manufacturers to produce precision-fitted bushing

slider washers that ensure optimal performance and reliability.

In summary, CuZn25Al6Fe3Mn4 C86300 graphite bronze is an excellent

material choice for bushing slider washers and other sliding

components. Its self-lubricating properties, high strength, good

corrosion resistance, and machinability make it suitable for a wide

range of applications where smooth and reliable sliding motion is

essential.

Oilless Thrust Washers | Solid Lubricant Washers - Select,

configure, order

• Maintenance free bronze oilless bushing, bronze with solid

lubricant

• Washer, self-lubricating

• Oilless Slide Plate

We Produce The Oilless Bushings According To Your Requirements.

Contact Us Now!

Cost performance graphite self-lubricating bearing, long life,

strong and durable

CuZn25A16Fe3Mn3 self-lubricating bearing is assembled from

CuZn25A16Fe3Mn3 copper matrix + graphite +, which is widely

suitable for high temperature, high load, low speed, medium load

and other occasions.

| Chemical Requirements |

Copper

Alloy

UNS No. | Composition, % max, except as indicated |

| | | | | Nickel | | | | | | |

| Copper | Tin | Lead | Zinc | Iron | Including | Aluminum | Manganese | Antimony | Sulfur | Phosphorus | Silicon |

| | | | | Cobalt | | | | | | |

| C86300 | 60.0–66.0 | 0.20 | 0.20 | 22.0–28.0 | 2.0–4.0 | 1.0A | 5.0–7.5 | 2.5–5.0 | ... | ... | ... | ... |

| C90500 | 86.0–89.0 | 9.0–11.0 | 0.30 | 1.0–3.0 | 0.20 | 1.0A | 0.005 | ... | 0.20 | 0.05 | 0.05B | 0.005 |

| C91100 | 82.0–85.0 | 15.0–17.0 | 0.25 | 0.25 | 0.25 | 0.50A | 0.005 | ... | 0.20 | 0.05 | 1.0B | 0.005 |

| C91300 | 79.0–82.0 | 18.0–20.0 | 0.25 | 0.25 | 0.25 | 0.50A | 0.005 | ... | 0.20 | 0.05 | 1.0B | 0.005 |

| C93700 | 78.0–82.0 | 9.0–11.0 | 8.0–11.0 | 0.8 | 0.7C | 0.50A | 0.005 | ... | 0.50 | 0.08 | 0.10B | 0.005 |

| A In determining copper minimum, copper may be calculated as copper

plus nickel. |

| B For continuous castings, phosphorus shall be 1.5 % max. |

| C Iron shall be 0.35 % max. when used for steel-backed. |

Chemical composition of materials

CuZn25A16Fe3Mn3(GB/T 1176-1987)=G-CuZn25Al5(DIN)=C86300(ASTM)

Chemical composition quality/% |

| Chemical composition quality/% |

| Cu | Sn | Al | Fe | Mn | Ni | Pb | Si | P | Zn |

| 60-66 | 0.2 | 5.0-7.5 | 2.0-4.0 | 2.5-5.0 | 1 | 0.2 | _ | _ | _ |

Mechanical properties of materials

| Tensile strength(Mpa) | Yield strength(Mpa) | Ductility% | Hardness (HB) |

| 785 | 424 | 14 | 225 |

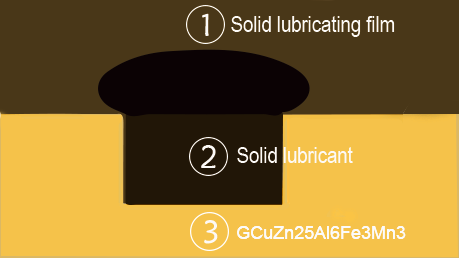

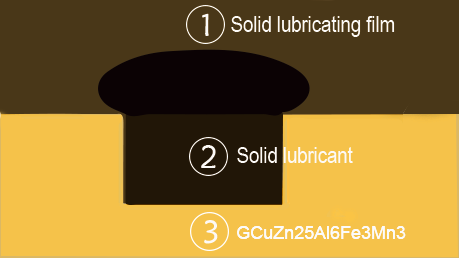

CuZn25A16Fe3Mn3 substrate made of solid lubrication oil-free

bearings (hereinafter referred to as solid embellish bearing), is

to use CuZn25A16Fe3Mn3 Gao Ligao strength as matrix, and embedded

radial arranged orderly cylindrical polymer filler for friction

materials (such as graphite, molybdenum disulfide, , oil

lubricant), its superiority lies in its made of copper alloy and

non-metallic antifriction material has the respective complementary

advantages, not only has high bearing capacity, and break through

the boundaries of generally depends on the oil film bearing grease

lubrication, achieve no oil lubrication, the embedded solid

lubrication easy lubrication film formation,It improves the

friction and wear performance greatly and is stable, reliable and

cost-effective.

CuZn25A16Fe3Mn3(C86300 graphite self-lubricating sleeve) graphite

self-lubricating sleeve composition

Using graphite in turns into granular features combined with filler

materials such as , forming a layer of oil film on metal surface

and the mixture of particles, reducing the bearing sleeve in

contact with the components of reducing friction, from

CuZn25A16Fe3Mn4 materials with good tensile strength, elongation,

and thermal conductivity, so the bearings used in high temperature,

high load, etc., etc of low speed and heavy loading.

CuZn25A16Fe3Mn4(C86300 Bearing) Bearing performance parameters

| Substrate material | CuZn25A16Fe3Mn3 | Maximum service temperature ℃ |

Ultimate dynamic load N/mm²

| 100 |

| The coefficient of frictionu | <0.16 | Maximum sliding speed m/s | dry/0.4 |

| Basic hardness HB | 210~270 | oil/0.5 |

Let's have a general idea of his production process

So the structures that you can choose are

You need to know more about the products you can choose

The following PDF is about the product information of

CuZn25A16Fe3Mn3 (C86300) in our company. You can choose different

product types or raw materials, or you can customize the size and

arrangement of graphite. In general, our company produces products

according to ISO 4379 standard.

Graphite

self-lubricating bearing.pdf

Where can be applied to CuZn25A16Fe3Mn3 (C86300 ) graphite

self-lubricating bearings and related products?

Metal self-lubricating bearings can be used for dry friction, high

temperature, high pressure, corrosive environment, moisture and

chemicals, and are widely used in automobile production lines,

water conservancy projects, reservoir gates, injection molding

machines, continuous casting machines, metallurgical machinery,

mining machinery, turbine generators, hydraulic generators and

other fields.

Advantages of our self-lubricating products

1. It can be used for a long time without maintenance;

2. Designed for high static load and dynamic load;

3. It has a very low and stable friction factor and no "sticking"

phenomenon;

4. Dust resistance, corrosion resistance, impact resistance and

edge load resistance;

5. Metal substrates have good shock absorption capacity;

6. Can be used in a wide range of temperatures;

7. Suitable for reciprocating, rotating and swinging, and other

starting frequent and difficult to form oil film occasions.