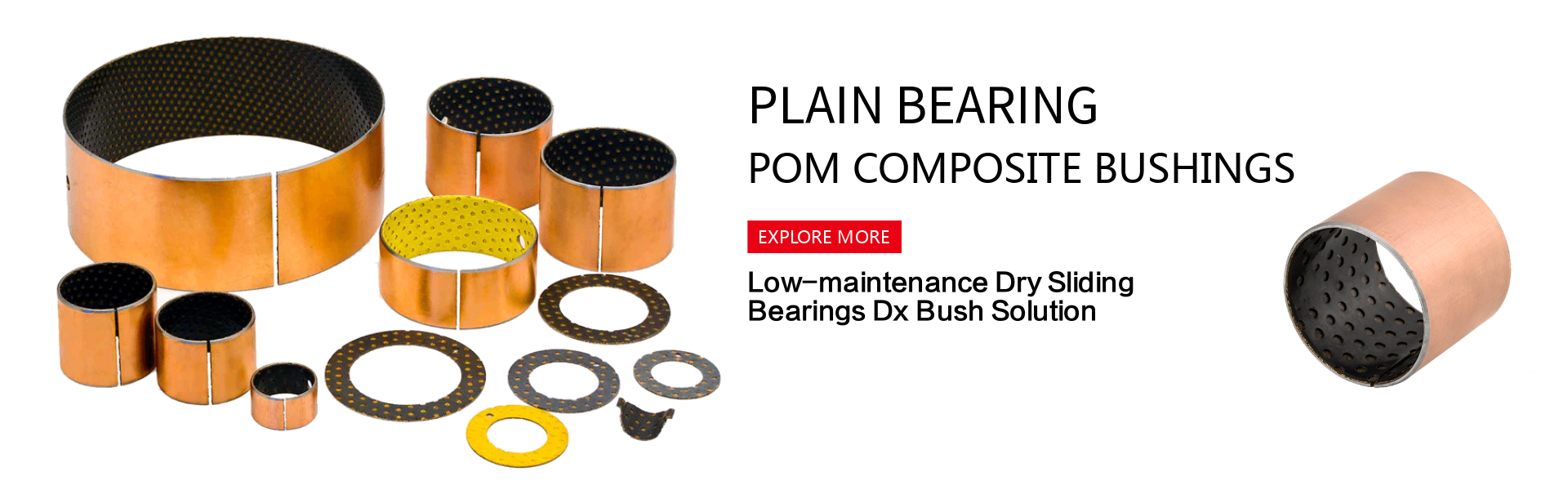

Sleeve acetal plastic POM (Polyoxymethylene) plain bearings, also known as composite bushings, are widely used in various applications due to their excellent wear resistance, low friction, and good mechanical properties. When these bearings are grease-lubricated, their performance and lifespan can be significantly enhanced. Here’s a detailed overview:

Key Features of Sleeve Acetal Plastic POM Plain Bearings:

Material Properties:

Polyoxymethylene (POM): Known for its high stiffness, low friction, and excellent dimensional stability.

Composite Structure: Often combined with other materials to enhance properties like load capacity and wear resistance.

Grease Lubrication:

Reduced Friction: Grease helps in minimizing friction between the bearing and the shaft, leading to smoother operation.

Wear Protection: Lubrication reduces wear and tear, extending the bearing's lifespan.

Corrosion Prevention: Grease can provide a protective layer against moisture and contaminants.

Applications:

Automotive: Used in various components like suspension systems, steering linkages, and door mechanisms.

Industrial Machinery: Ideal for conveyor systems, agricultural equipment, and packaging machinery.

Consumer Electronics: Found in appliances and other devices requiring low-friction movement.

Advantages:

Self-Lubricating: Some POM bearings have self-lubricating properties, reducing the need for frequent maintenance.

Noise Reduction: Grease-lubricated bearings operate more quietly.

Load Capacity: Enhanced load-bearing capacity due to the composite structure and lubrication.

Maintenance:

Regular Lubrication: Periodic application of grease is necessary to maintain optimal performance.

Inspection: Regular checks for wear and tear to prevent unexpected failures.

Selection Criteria:

Load and Speed: Consider the operational load and speed to select the appropriate bearing.

Environmental Conditions: Factor in temperature, humidity, and exposure to chemicals.

Shaft Material: Ensure compatibility between the bearing and the shaft material to avoid excessive wear.

Installation Tips:

Proper Fit: Ensure the bearing fits snugly without excessive force.

Alignment: Proper alignment of the shaft and bearing is crucial to avoid uneven wear.

Lubrication: Apply grease evenly during installation to ensure smooth operation from the start.

Common Issues and Solutions:

Overheating: Often due to inadequate lubrication or excessive load. Ensure proper grease application and check load ratings.

Wear: Regular inspection and timely replacement of worn-out bearings can prevent machinery damage.

Noise: Unusual noises may indicate misalignment or insufficient lubrication. Re-align and re-lubricate as necessary.

By understanding these aspects, you can effectively utilize sleeve acetal plastic POM plain bearings in your applications, ensuring reliable and efficient performance.

Our Sleeve Acetal Plastic POM Plain Bearings are grease-lubricated composite bushings designed to provide exceptional performance in a wide range of industrial applications. These bearings are made from high-quality acetal plastic (POM), which offers excellent mechanical properties, chemical resistance, and wear resistance.

The grease lubrication system ensures smooth and reliable operation of the bearings, reducing friction and wear. This lubrication method is particularly suitable for applications where traditional oil lubrication is not feasible or practical.

The composite bushings of our POM plain bearings are designed to provide optimal load distribution and reduce stress concentrations. This ensures longer bearing life and improved performance, even under high loads and high-speed conditions.

Our Sleeve Acetal Plastic POM Plain Bearings are precision-manufactured to ensure accurate dimensions and smooth surfaces. This ensures a perfect fit and optimal performance in your specific application.

Wh you need bearings for machinery, equipment, or any other industrial use, our grease-lubricated composite bushings are an excellent choice. They are easy to install and maintain, reducing downtime and maintenance costs.

We are committed to providing high-quality products and exceptional customer service. Our Sleeve Acetal Plastic POM Plain Bearings are backed by our commitment to quality and satisfaction. Contact us today to learn more about our bearings and how they can improve the performance of your industrial operations.

POM coated bush based steel backing with POM inner layer, oilless bearing,POM bushing and POM lined plain dry bush. High quality bronze bushing from China, bearings can be widely used as components necessary in mechanical industries or for repair and maintenance of various machines.

POM Split Bush Bearing - Oil or grease lubricated bearings.

POM coated boundary lubricating bearing (POM bushing)

Bushing Finder. Part Finder. Bushing Form:Cylindrical Bushes, Flange Bushing

Thrust Washers, Sliding Plates, Flange Washer, Select Type: Metal-Polymer Plain Bearings,Solid Bronze, Bimetal Bushing, Solid Bushing Bronze With Lubricant Plugs Embedded, Composite Bushing, Wrapped Bushing Bronze CuSn8, Lubrication Depots, Search By Bushing Size. Select Size. Metric Or Imperial Size, Inner Diameter, Length

Base Material. Please Select Flange Outer Diameter,Flange Thickness.

You have access to the latest downloads here. Click on the Wrapped Composite Sliding Bearing.pdfcatalog symbol to display the file, and download the self-lubricating bushing bearings catalog file.

Bushings: Pre-Lubricated Inch Series,Inch Composite Plain Bushings

Steel-Sintered-Bronze-POM Composite Material low-maintenance.Steel with porous sintered tin bronze layer, which is coated with POM as sliding layer.Bronze and plastic/polymer bushings available upon request.

Looking for a PTFE bush, POM Bushing,Metal-Polymer Low Friction Plain Bearings,PAP P10 P20 Bronze Bush alternative? Get a quotation online for cylindrical series in metric measurements.Need Help Finding the Right Self-lubricating Bronze Bushing Product?Our Plain Bearings Parts Experts Can Help. Call for immediate assistance.Bushing & Sliding Bearing Manufacturer | Metric Cylindrical Bushing I The POM Bushing Alternative.What We Do Manufacturing Self-lubricating Plant Certifications Design Challenge Industry Solutions.Steel/POM Bushing,metric & inch sizes.Wall,Thickness Shaft,Diameter Housing,ID Installed Bushing ID Clearance Order Online.Bush, Bushing, Metric Cylindrical Series Size in Metric.

POM REPLACEMENT BUSHING PARTS SIZE CHART

| Unit(metric size): mm |

| d | D | Shaft | BoreH7 | Wall

Thickness | h

Lubricating | f1 | f2 | |

| Min. | Max. | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

| 10 | 12 | 10-0.022 | 12+0.018 | 0.955 | 0.980 | 4 | 0.6 | 0.3 | 1010 | 1015 | 1020 | | | | | | | |

| 12 | 14 | 12-0.027 | 14+0.018 | 1210 | 1215 | 1220 | | | | | | | |

| 14 | 16 | 14-0.027 | 16+0.018 | | 1415 | 1420 | | | | | | | |

| 15 | 17 | 15-0.027 | 17+0.018 | | 1515 | 1520 | 1525 | | | | | | |

| 16 | 18 | 16-0.027 | 18+0.018 | | 1615 | 1620 | 1625 | | | | | | |

| 18 | 20 | 18-0.027 | 20+0.021 | | 1815 | 1820 | 1825 | | | | | | |

| 20 | 23 | 20-0.033 | 23+0.021 | 1.445 | 1.475 | 0.6 | 0.4 | | 2015 | 2020 | 2025 | 2030 | | | | | |

| 22 | 25 | 22-0.033 | 25+0.021 | | 2215 | | 2225 | | | | | | |

| 25 | 28 | 25-0.033 | 28+0.021 | 6 | | 2515 | 2520 | 2525 | 2530 | | | | | |

| 28 | 32 | 28-0.033 | 32+0.025 | 1.935 | 1.970 | 1.2 | 0.4 | | | 2820 | | 2830 | | | | | |

| 30 | 34 | 30-0.033 | 34+0.025 | | | 3020 | 3025 | 3030 | 3035 | | | | |

| 35 | 39 | 35-0.039 | 39+0.025 | | | 3520 | | 3530 | 3535 | | | | |

| 40 | 44 | 40-0.039 | 44+0.025 | 8 | | | 4020 | | 4030 | 4035 | 4040 | | 4050 | |

| 45 | 50 | 45-0.039 | 50+0.025 | 2.415 | 2.460 | 1.8 | 0.6 | | | 4520 | | 4530 | | 4540 | 4545 | 4550 | |

| 50 | 55 | 50-0.039 | 55+0.030 | | | | | 5030 | | 5040 | | 5050 | 5060 |

| 55 | 60 | 55-0.046 | 60+0.030 | | | | | 5530 | | 5540 | | 5550 | 5560 |

| 60 | 65 | 60-0.0463 | 65+0.030 | | | | | 6030 | | 6040 | | 6050 | 6060 |

| Unit(METRIC SIZE POM BUSHING): mm |

| d | D | Shaft | BoreH7 | Wall

Thickness | h

Lubricating | f1 | f2 |

L0

-0.40

|

| Min. | Max. | 40 | 50 | 60 | 80 | 90 | 95 | 100 | 110 | 120 |

| 65 | 70 | 65-0.046 | 70+0.030 | 2.415 | 2.460 | 8 | 1.8 | 0.6 | 6540 | | 6560 | | | | | | |

| 70 | 75 | 70-0.046 | 75+0.030 | 7040 | 7050 | | 7080 | | | | | |

| 75 | 80 | 75-0.046 | 80+0.03 | 7540 | | 7560 | 7580 | | | | | |

| 80 | 85 | 80-0.046 | 85+0.035 | 2.385 | 2.450 | 9.5 | 1.8 | 1.8 | 8040 | | 8060 | 8080 | | | | | |

| 85 | 90 | 85-0.054 | 90+0.035 | 8540 | | 8560 | 8580 | | | | | |

| 90 | 95 | 90-0.054 | 95+0.035 | 9040 | | 9060 | 9080 | 9090 | | | | |

| 100 | 105 | 100-0.054 | 105+0.035 | | 10050 | | 10080 | | 10095 | | | |

| 105 | 110 | 105-0.054 | 110+0.035 | | | 10560 | 10580 | | 10595 | | 105110 | |

| 110 | 115 | 110-0.054 | 115+0.035 | | | 11060 | 11080 | | 11095 | | 110110 | |

| 120 | 125 | 120-0.054 | 125+0.040 | 1.8 | 0.6 | | | 12060 | 12080 | | | | 120110 | |

| 125 | 130 | 125-0.063 | 130+0.040 | | | 12560 | | | | | 125110 | |

| 130 | 135 | 130-0.063 | 135+0.040 | | 13050 | 13060 | 13080 | | | 130100 | | |

| 140 | 145 | 140-0.063 | 145+0.040 | | 14050 | 14060 | 14080 | | | 140100 | | |

| 150 | 155 | 150-0.063 | 155+0.040 | | 15050 | 15060 | 15080 | | | 150100 | | |

| 160 | 165 | 160-0.063 | 165+0.040 | 9.5 | | 16050 | 16060 | 16080 | | | 160100 | | |

| 170 | 175 | 170-0.063 | 175+0.040 | | 17050 | | 17080 | | | 170100 | | |

| 180 | 185 | 180-0.063 | 175+0.040 | | 18050 | 18060 | 18080 | | | 180100 | | |

| 190 | 195 | 190-0.072 | 195+0.046 | | 19050 | 19060 | 19080 | | | 190100 | | 190120 |

| 200 | 205 | 200-0.072 | 205+0.046 | | 20050 | 20060 | 20080 | | | 200100 | | 200120 |

| 220 | 225 | 220-0.072 | 225+0.046 | 9.5 | | 22050 | 22060 | 22080 | | | 220100 | | 220120 |

| 240 | 245 | 240-0.072 | 245+0.046 | | 24050 | 24060 | 24080 | | | 240100 | | 240120 |

| 250 | 255 | 250-0.072 | 255+0.052 | | 25050 | 25060 | 25080 | | | 250100 | | 250120 |

| 260 | 265 | 260-0.081 | 265+0.052 | | 26050 | 26060 | 26080 | | | 260100 | | 260120 |

| 280 | 285 | 280-0.081 | 285+0.052 | | 28050 | 28060 | 28080 | | | 280100 | | 280120 |

| 300 | 305 | 300-0.081 | 305+0.052 | | 30050 | 30060 | 30080 | | | 300100 | | 300120 |

The Plain Bearings Tolerance Size - To Provide Customers With Accurate Bushings Specification

VIIPLUS INTERNATIONAL Precision Relubricatable bushes type Sliding Bearing china supplier offers self-lubricating bearings services, custom packaging, kitting, and special shipping options. We are the solution provider to all of our customers. Sliding bearing selector bore inch metric size type straight bushing flanged bushing and thrust washers bore inside diameter and outside diameter choose bushing thin section type. Bronze and plastic/polymer bushings available upon request. Nominal Bearing Bore Recommended Installed Bearing ID* Bearing Length

Pom Composite bushing Characteristics

Pom Composite lubricated bushing can be used for grease or oil lubrication applications, or in an oil-free environment

The standard parts contain grooves in the sliding layer of the contact parts, which can store grease or friction debris.

A smooth sliding layer can be designed and provided upon request

The composite bearing sleeve has the best performance under relatively high load and low speed, and the highest relative life

Composite bearings are used in environments of linear, oscillating and rotational motion

All kinds of bearing parts are available from stock

A brief introduction to polyformaldehyde (POM) materials

1.with high mechanical strength and rigidity;

2. The Maximum fatigue strength;

3. Good environmental resistance and organic solvent resistance;

Strong resistance to sustained impact;

5. Widely used temperature ranges from -40℃ to 120℃.

6. Good electrical properties.

7. Good recovery.8, with their own lubrication, good wear to hold;9. Excellent dime

Melting point of 175 ° C

Density 1.42 g/mL at 25 °C

Flash point 158 °F storage condition 2-8°C

Self-lubricating oil-free composite bearing structure composition

Wrapper Bronze Bearing characteristics

| Performance indicators | Date |

| Maximum load | Static load | 250N/mm² |

| Dynamic load | 150N/mm² |

| Maximum linear velocity V | Grease lubrication | 2.5m/s |

| High PV value | Grease lubrication | 2.8N/mm²・m/s |

| Coefficient of friction | Grease lubrication | 0.05~0.25 |

| The use of temperature |

-40℃~+130℃ |

| Coefficient of thermal conductivity | 4W/m・K |

| Coefficient of thermal expansion | 12×10-6/K |

Areas Of Application:

The Pom Lubricating Bushes are suitable for rotary and oscillatory motions. Initial lubrication with grease is advisable, and a continuous lubricant feed substantially lengthens the service life of the slide bearing. for example,Fixing eyes for pneumatic and hydraulic cylinders Agricultural equipment

Wrapped Acetal Lined Bearings Plain Bearings, Self-Lubricating Bushings & Polymer Coatings Manufacturer

Assembly Shapes & Forms

Plain cylindrical bearings, thrust washers and sliding plates.POM STEEL BUSHINGS already prepared for assembly. The bushings are so designed that when press-fitting the bearing into the housing, the mating gap can be eliminated. However, the mating-point of the bearing should be positioned away from the load-zone.

Special Manufacturing Bushings:

Rod end bearings/spherical plain bearings/journal bearings On request, we can offer inch-sizes, standard size drawing,Lubrication Bearings, washers or sheets Strips.

Viiplus Pom Bushings

offers a broad range of sizes, forms and materials in monometallic and bearings. Bimetal and metal bearings offer excellent corrosion resistance in industrial outdoor applications and in water, marine and offshore environments.

Metal-Polymer Plain Bearings Grease Lubricated

POM is a triple layer bearing consisting of copperplated steel frame, a middle layer of sintered bronze and a sliding surface of acetal plastic (POM).The sliding surface is provided with grease pockets which embeds the lubricant for gradual

release during operation. The slip layer also has a good ability to embed dirt and small particles that could damage the shaft. POM can withstand relatively high loads and is suitable for rotary and oscillating movements and structures with frequent starts and stops.

Technical data

| Performance indicators | Date |

| Maximum load P | Static load | 250N/mm² |

| Dynamic load | 150N/mm² |

| Maximum linear velocity V | Grease lubrication | 2.5m/s |

| High PV value | Grease lubrication | 2.8N/mm²・m/s |

| Coefficient of friction μ | Grease lubrication | 0.05~0.25 |

| The use of temperature |

-40℃~+130℃ |

| Coefficient of thermal conductivity | 4W/m・K |

| Coefficient of thermal expansion | 12×10-6/K |

Metallographic image

Note: note: VSB-20 series products can also choose different matrix materials according to different working conditions, such as: bronze substrate, stainless steel substrate, and "lead-free" formula products.Hxob-20y is an environmentally friendly lead-free product with the colors of orange, orange and blue.

Description

VSB20 abroad (POM) boundary lubrication bearing with high quality low carbon steel or copper plate as substrate, the middle sintered porous spherical bronze powder, the friction surface rolling modified polyformaldehyde (POM and Pb), and through the high temperature solid combination as one of the three layers of plasticizing boundary lubrication bearing materials (also called prelubricated bearing material), the rolling and sliding bearing.

The material can provide better bearing capacity and wear resistance, friction surface with oil pits, in the presence of a small amount of lubrication medium, its performance is better than other sliding bearing materials.The product is suitable for working under normal temperature and medium (heavy) load, low speed occasions, to replace the traditional copper sleeve, which reduces the cost and extends the service life.Boundary lubricated bearings are divided into steel base and copper base.

Availability

Bearing forms available in standard dimensions

Cylindrical bushes

Thrust washers

Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping, bearings with locating notches, lubricant holes and machined grooves, customized bushing designs

Suitable for use in fatting or lubricating conditions, high bearing capacity, good wear resistance;

Suitable for rotating, reciprocating and swinging and other forms of movement and frequent starting, intermittent movement or heavy load and other occasions which are not easy to form oil film lubrication;

High load, low speed lubrication conditions with stable low friction coefficient and excellent wear resistance;

Friction surface layer can be secondary processing, bearing into the seat hole after processing, can further improve the accuracy of fit;

Long working time under boundary lubrication conditions, such as in the process of regular grease maintenance, can extend the service life;

Bearings for thin-wall structure, light weight, occupies a small volume, suitable for compact design;

Good dimensional stability, high mechanical strength;

Strusture

1. POM thickness 0.30~0.50 mm. It provides high wearresistance and low friction even with only minute volume oflubricant are supplied, this bearing surface carries a pattern of circular indents which should be filled with grease on assembly of the bearing.

2. Sintered bronze powder thickness 0.20-0.35mm. A special composition of powdered copper is thermally fused to the steel backing. This contact layer acts as an anchor for the layer and conducts the thermal build up away from the bearing surfaces.

3. Low-carbon steel.Setting the foundation of the bushings, the steel back provides exceptional stability,load carrying and heat dissipation characteristics.

Typical Applications

VIIPLUS sliding bearings are used in a wide range of applications in all industries.

Widely used in hydraulic and pneumatic industry, forging machine industry, plastic machinery industry, lifting and handling machinery, port machinery, office, fitness machinery, textile machinery, food packaging, filling machinery, chemical machinery, printing bags, paper machinery, automobiles, railways Automobile locomotive, shipbuilding industry, plastic machine industry, metallurgical machinery, engineering machinery, etc.

Hydraulic machinery: hydraulic steel gate plane support slide, etc.Hydraulic turbine: guide vane (upper guide, middle guide, lower guide) shaft sleeve, wheel shaft sleeve, pin shaft sleeve (connecting rod pin, push and pull rod pin, relay piston pin), anti-wear ring plate (thrust ring), anti-wear block, control ring side tile.Hoisting and transport machinery: forklift lifting device, gantry crane and pulley block, brake, stacker resorter hinge, shore lifting support hinge seat, etc.Oil machinery: pumping unit reducer intermediate shaft and output shaft sleeve, etc.Valve industry: butterfly valve, globe valve, etc.

We offer extensive flexibility to our customers by offering not only standard bushings products but offering our customers a broad array of our manufacturing partners to supply unique items for their specific applications.